Made in the UK – The Devon Disability Collective going from Strength to Strength

The Devon Disability Collective (DDC) formed in July 2015 and was a ‘workers collective’ takeover from the previous owners who planned to close the factory and would have otherwise led to many of the employees being made redundant. The purpose of the Social Enterprise is to provide employment for people with disabilities and those furthest from the labour market. The site in its hay day employed 70 people. The business was saved from closure by the Union, local Council – notably the Council leader John Hart and by the Local Labour MP Ben Bradshaw and not to mention all the loyal staff.

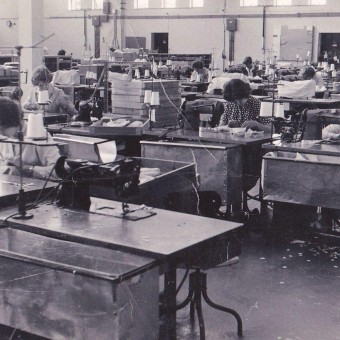

The Devon Disability Collective is based on the Marsh Barton Trading Estate Exeter which in the 1950’s once housed the Gossard Underwear Factory, you might recall it had a 10ft statue on the roof of Venus De Milo! Rumour has it, she now lies in a field in Tedburn. The building as it so happens was the first to be built on Marsh Barton by Norman Pratts. Gossards came to Exeter in the mid 1950’s as the city had a surplus of female labour wishing to be trained as sewing machinists. The north wall of the factory was a temporary fabrication with the view to future expansion, but this never came to fruition.

In 1960 the factory was flooded when the Alphington brook burst its banks with 10 inches of water on the factory floor. The underground wiring was replaced with temporary overhead wiring and the factory was back up and running within a week.

Gossards most successful garment was the Wonder Bra, brought over from Canada through a licensing agreement with a lingerie company called Montreal by the Factory manager Bill Healy and the directors at the time. Canadelle’s bra that had been developed to enhance bust cleavage had been marketed in Canada but later dropped from its range as it was seen as not suited to the Canadian market. It was Bill and his colleagues however that saw the potential of this bra that was further developed by Gossard and given the name “Wonder Bra”, this later became a worldwide success, driven by a powerful marketing campaign. The production methods of this bra were developed and manufactured at the Exeter factory. During the 1970’s the Exeter factory was the first in the UK to develop systems for moulding seamless Bra Cups, this was then followed by a manufacturing facility at the Exeter plant.

In the early 1980’s female labour became in short supply as other prestigious jobs were on the market. In an attempt to employ previous girls that had left to have a family, a cress was opened, but this never really took off. In 1984 with the threat of cheaper overseas labour, Gossard decided to close its Exeter Factory and reopened a plant in Mendez Messel, Tunisia. The choice was between Exeter and the Blackwood factory, but with the Welsh industrial grants and the abundance of trained labour in Wales, it was Exeter that had to go, and there were around 100 redundancies.

The coming about of the Devon Disability Collective to the Gossards site dates back to the 1960’s in George Street where the business was called ‘The Workshop for the Disabled’ and in 1985 they out-grew these premises and moved to the old Gossard site on Marsh Green Road, Marsh Barton.

The business ever since its infancy has provided specialist long term employment and training for people with disabilities. The name later changed to Exeter Industrial services and gained a large supply agreement from the NHS for Wheelchair products which made the factory thrive, for just one size of wheelchair seat alone over 15,000 were produced in a month, other items included wheelchair backs, trays and cushions, filling up great Artic lorries at a time. A team of 5 welders would heat seal the seats (machine stitched today) and it was hard to keep up with demand. In the 1980’s a flywheel press was invested in to cut material, something that would not pass Health and Safety Practice in this current age by a long-shot, this sped up production 100 fold, previously these were cut by hand with a Stanley Knife. Table frame welding was also popular in the 80’s supplying lots of local schools and also clinical gowns for hospitals and blue wooden pallets!

Competitors cottoned on to the success of the business with its wheelchair products and with the likes of China offering cheaper lower grade production alternatives orders decreased, and the business quickly responded by offering a wider range and bespoke products in all shapes and sizes. The biggest edge the business had was time responsive being able to make a modification product for a wheelchair within a day or two, that in numerous cases were seen as being a lifesaver for the individual, keeping them mobile, especially for the young or terminally ill.

Innovation and the desire to make a difference has always played a large part in our history, in 2007 we developed a tamper-proof belt in response to the tragic death of a wheelchair user. This product gained approval by the MHRA.

The Devon Disability Collective as it stands today has a real diverse portfolio, Wheelchair products for the NHS and private sector, contract sewing, Contract packing for telecoms and re-upholstery for the rejuvenation of old furniture, classic cars and campervans and motorbikes. The variety of work for the staff in upholstery is fantastic as it brings lots of interesting challenges and feedback has been amazing too, giving new life to well-loved possessions is very satisfying. The mobility showroom, another string to DDC’s bow, opened its doors last July and is growing in range by the day and we have already built great relationships with Electric Mobility (as a recommended retailer) and AJ way. We have just embarked on doing home assessments too for the less abled and repairs.

The most satisfying thing about working for DDC is the knowledge that with this social enterprise all profits get ploughed back into the business to help recruit more people with little or no chances of finding employment in Devon. The prices are all reasonable too as there is no need to make massive corporate profits to satisfy shareholders.

David Healy son of Bill Healy’s – Recollection of the factory

David Healy, now 68 and living on the Isle of Wight, remembers his father Bill moving to Exeter after managing Gossard’s factory in Croydon, Surrey.

“I can remember the Gossard’s Venus de Milo well. I seem to recall that I actually first saw it before it was installed on the roof of the building; it was a beautiful golden colour, and slightly embarrassing to a ten-year-old boy because she had, well, boobs! Incidentally, I recall that the statue was made of concrete rather than metal, although it may well have had an interior metal frame.

“I also seem to recall that the inspiration for the statue may have originated from the then company chairman of Gossard, the late Sir Basil Lindsay-Fynn, who had a fine house at Lee Ford near Budleigh Salterton.

“In the late 50s I visited the grounds of Lee Ford for what was essentially a country fete, and seeing a “concours d’elegance” of vehicles which included two iconic new vehicles; the Austin Healy Sprite Mk 1 – now known as the “Frogeye Sprite – and a Morris Mini. The latter caused much interest, but what sticks in my mind is indicative of cars of that era; with the Mini’s innovative sideways-mounted engine, I wondered where on earth the starting handle would go!

“My father’s bottle-green Austin A30 Countryman certainly had a starting handle, and I remember him teaching me how to hold it correctly so that if the engine “kicked back” whilst being started the handle would not break your thumb.

“That car was much used by my father in transporting Gossard factory staff when needed. I recall him managing to squeeze in no fewer than eight of “the girls” – one in the front passenger seat and two in the rear seats, with one girl each on their laps. And two more sitting sideways opposite each other in the luggage space! Today’s Health and Safety jobsworths, and I’m sure the current constabulary, would have had apoplectic fits – but in those days, it didn’t seem to cause a problem.

“The floods recalled by my sister Rosamond certainly did cause huge problems for the factory. Although the staff worked furiously to raise as much valuable fabric as possible to higher levels to beat the flood water, they could do nothing to stop one problem.”

“As a clothing business, Gossard had a plethora of different types of sewing machines to deal with the different kinds of stitching required. The designers had come up with a way of avoiding unsightly and possibly dangerous electrical cables snaking down from above – by installing floor-mounted electrical sockets. Not surprisingly, these suffered badly when immersed in flood water, but did eventually get dried out.

“The clearing up operation started even before the flood waters had completely receded. I joined my father and other workers in wading to the factory after climbing up onto the old railway embankment and walking along the disused line to get close enough. We were unable to drive closer, even with the “snorkel” device rigged up on the A30 Countryman, because the road dipped under the old Marsh Barton railway bridge and made the water too deep.

“Once at the factory, the horribly smelly flood water had to be washed and brushed from the floor by hand, with liberal use of Jeyes fluid as a disinfectant. That proved to have an equally powerful smell, and the whole job had to be repeated using Pine’s disinfectant!

“A few other points come to mind about the Gossard factory. My father had worked hard to recruit staff for the new concern, and was conscious of the value of publicity. I don’t remember how he did it, but somehow the Bishop of Crediton was invited to officiate at the opening ceremony, which was held in the staff canteen to the right of the main entrance.

“I remember my father saying he was a bit concerned that the Bishop might be tempted to refer to the “foundation garment” factory with a quote along the lines of “The Church is one foundation” – but he didn’t. In retrospect, I suspect my father would have appreciated the publicity if the Bishop had said it!

Publicity, and providing an interest for the factory staff, was often something Bill aimed for. On one occasion, a singer and comedian was appearing in an Exeter theatre and my father somehow managed to get him to visit the factory; the staff were hugely impressed by a youngish Ken Dodd.

My sister and I were both allowed to visit the factory on this occasion; I don’t know if she still remembers it, but the young Rosamond was given an individual few bars of “Love is Like a Violin” by a completely charming and natural Ken Dodd in my father’s office.

The offices were – and probably still are – on the first floor at the front of the factory. In the early days, the Marsh Barton Trading Estate was in its infancy and Gossard’s was largely surrounded by flat fields. My father related his surprise at the slightly surreal sight from his office of a coaster chugging through the fields – although it was evidently there, you couldn’t actually see the Exeter Ship Canal!

Gossard’s was eventually taken over by Courtaulds, but retained its individuality. Over the years Bill Healy rose to became managing director and joint chairman of the company before eventually starting his own business. He passed away in 2009, but he left one legacy of which he had always been rather proud – it was Bill who introduced the Wonderbra from Canada to be made by Gossard in the UK.

Ros Blackburn daughter of Bill Healy – Recollection of the factory

Attached photo shows the Gossard building during the Great Flood of 1960. The building had only opened in September 1957, and sadly many of the fine interior fittings were never quite the same after being soaked by the flood water.

Panic was rising in the building along with the flood water on that day in 1960 – it was Alphin Brook that broke its banks, and the water could be seen advancing slowly up the road towards the factory. The Factory Manager, Bill Healy, walked down and placed a brick in the middle of the road, about 20 ft in front of the flood water. He told the staff that the building would be evacuated once the flood water reached the brick, and with panic under control set everyone to work preparing (as much as possible) for the flood – fine satins and expensive laces were placed up as high as possible, along with work in progress, and a controlled shut down of the building’s machinery took place. The workers would check out of the window every now and then, to make sure that the water hadn’t yet reached the brick. What they didn’t know was that Bill had briefed the yard foreman to go out and move the brick back every quarter of an hour, so there was always a generous gap to the water.

A couple of hours later the water reached the point that Bill had decided in advance was the real crisis point, and he sent the workers home – nobody was allowed to go alone, they all set off in groups, with a manager or supervisor in charge, heading for similar parts of town – the leaders were tasked with making sure that everybody in their group made it to safety.

Bill’s company ‘car’ at the time was an Austin A30 van, and he had recently become a founder member of Exeter’s Rotary Group. He rigged up a pipe from the exhaust, running it up to the roof of the van. Taking off his shoes and socks, with exhaust fumes puffing from the top of the pipe, he drove through the floods with water up to his ankles, helping to delivery Rotary food parcels to old people who had been cut off by the floods.

Bill moved back to Gossard at Leighton Buzzard in 1963, but always had fond memories of his six years in Exeter.

We continue to team up with like-minded local and national organisations and have recently offered factory space to DS Smith – for the assembling of Cartons and Hidden Gems who support people with mental health and other challenges, getting people back into work in-line with our ethos.

If you were a Gossard girl, or worked for us in the past, or even know the whereabouts of Venus De Milo! it would be great to hear from you we could look to putting on a reunion. Contact: Luke Rogers at: Luke@devondisabilitycollecitve.org

Big thanks to Desmond Chudley, David Healy and Ros Blackburn for helping me with this story and the photos and Dave Webber DDC’s current Production Director for information. If you would like to learn more about the Devon Disability Collective or get in touch with us please visit www.devondisabilitycollective.org or call 01392 428585.

We are always looking for helpers and would be delighted to hear from any experienced fundraisers, further if you did want to make a small donation to the Collective, this can be done through our website or facebook page.